Harnessing the Power of AI in Mechanical Engineering Design

created on 02/05/2025

The intersection of Artificial Intelligence (AI) and mechanical engineering marks a pivotal moment in the evolution of product design and manufacturing. As we stand at the cusp of this technological revolution, the integration of AI is fundamentally changing how engineers approach complex problems, optimize solutions, and push the boundaries of innovation.

The AI Revolution in Engineering Design

Artificial Intelligence isn't just another tool in the engineer's toolbox—it's a paradigm shift that's redefining the entire design process. Modern engineering challenges demand solutions that can handle increasing complexity while meeting strict deadlines and cost constraints. AI is proving to be the key to unlocking these demanding requirements.

Rotating Mechanism For Robotic Hand

AI-Driven Design Optimization

The traditional approach to design optimization often relied heavily on engineer intuition and iterative testing. While valuable, this method could only explore a limited number of possibilities. AI algorithms have transformed this landscape by:

- Processing vast datasets of material properties, performance metrics, and design constraints simultaneously

- Identifying non-obvious relationships between design parameters

- Suggesting optimal solutions that balance multiple competing objectives

- Reducing the time needed to arrive at viable design solutions

For instance, when designing a new hydraulic pump, AI algorithms can simultaneously analyze hundreds of variables—from fluid dynamics to material stress distributions—to suggest designs that maximize efficiency while minimizing manufacturing costs.

The Power of Generative Design

Generative design represents one of the most revolutionary applications of AI in mechanical engineering. This approach turns traditional design methodology on its head by:

- Starting with design goals and constraints rather than predetermined solutions

- Exploring thousands of possible design iterations simultaneously

- Learning from each iteration to produce increasingly optimized designs

- Suggesting novel solutions that human designers might never have conceived

Airship Bracket Concept Iterations

Engineers can now input specific parameters such as maximum weight, minimum strength requirements, manufacturing methods, and material choices, and receive dozens of viable design options. Each solution meets the technical requirements while potentially offering unique advantages in terms of cost, manufacturability, or performance.

Beyond Design: AI in Manufacturing and Maintenance

Smart Manufacturing Integration

AI's influence extends well beyond the design phase into manufacturing processes. Modern manufacturing facilities are increasingly equipped with AI-powered systems that:

- Optimize production line configurations in real-time

- Adjust manufacturing parameters automatically to maintain quality

- Predict and prevent bottlenecks in production flow

- Reduce material waste through intelligent resource allocation

Advanced Predictive Maintenance

The implementation of AI in maintenance systems has revolutionized how we approach equipment reliability. Modern predictive maintenance systems can:

- Monitor equipment health in real-time through sensor networks

- Detect subtle changes in performance that might indicate future problems

- Predict maintenance needs weeks or months in advance

- Optimize maintenance schedules to minimize production disruption

Ai Driven Manufacture Center

This capability has proven particularly valuable in industries where equipment downtime can cost millions of dollars per day. By accurately predicting when maintenance will be needed, companies can schedule repairs during planned downtimes rather than dealing with unexpected failures.

Virtual Prototyping and Testing

The integration of AI into testing and prototyping has dramatically reduced development cycles while improving product reliability. Modern AI-powered testing systems can:

- Simulate complex real-world conditions with unprecedented accuracy

- Identify potential failure modes that might be missed in physical testing

- Reduce the number of physical prototypes needed

- Accelerate the certification process for new designs

For example, an automotive component that previously required dozens of physical prototypes can now be extensively tested in virtual environments, with AI models predicting performance under various conditions before a single physical part is produced.

Fostering Collaborative Innovation

AI tools are breaking down traditional barriers in engineering collaboration by:

- Enabling real-time sharing of complex design iterations

- Providing data-driven insights that all team members can understand and build upon

- Facilitating cross-disciplinary collaboration through common platforms

- Automating routine tasks to allow focus on creative problem-solving

The Future of AI in Mechanical Engineering

As AI technology continues to evolve, we can expect to see:

- More sophisticated integration between AI and CAD systems

- Enhanced ability to learn from historical design data

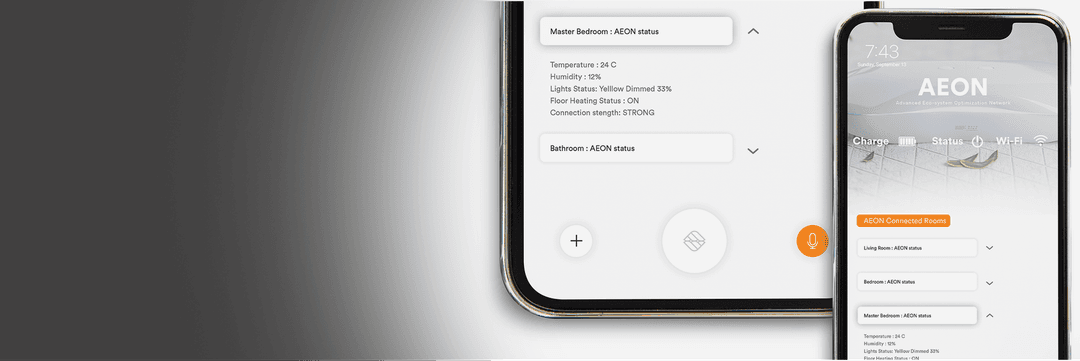

- Improved natural language interfaces for engineering software

- Greater automation of routine engineering tasks

The key to success will lie in finding the right balance between human creativity and AI capabilities. While AI can process vast amounts of data and suggest optimal solutions, human engineers bring invaluable experience, intuition, and creative problem-solving abilities to the table.

Conclusion

The integration of AI into mechanical engineering represents more than just a technological advancement—it's a fundamental shift in how we approach design and problem-solving. As we continue to explore and expand the capabilities of AI in engineering, we're not just improving efficiency; we're opening new possibilities for innovation and creativity in mechanical design.

The future of mechanical engineering lies in the successful partnership between human expertise and AI capabilities. By embracing these technologies while maintaining focus on practical, implementable solutions, we can push the boundaries of what's possible in mechanical engineering.

Share this article

Oana Agavriloaie is a software developer and product designer with a passion for creating innovative solutions that drive business growth. With a background in computer science and design, Oana combines technical expertise with creative vision to deliver impactful software solutions that meet the unique needs of clients. Her commitment to excellence and customer satisfaction has made her a trusted partner for businesses seeking to transform their operations through technology.

Related Articles

The Power of Software: How Custom Solutions Can Transform Your Business

From Concept to Creation: A Mechanical Engineer's Roadmap to Successful Product Design